* Required fields

Pile calculation program (According to NP 123: 2010)

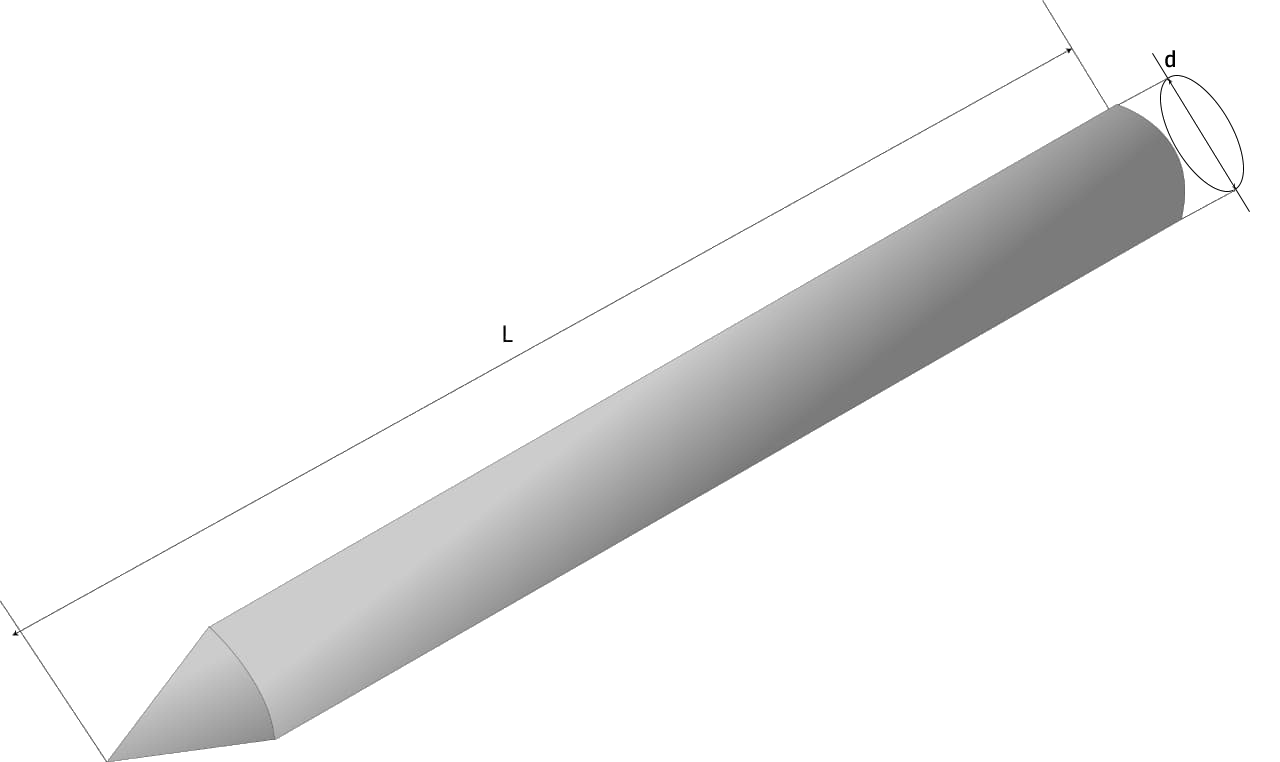

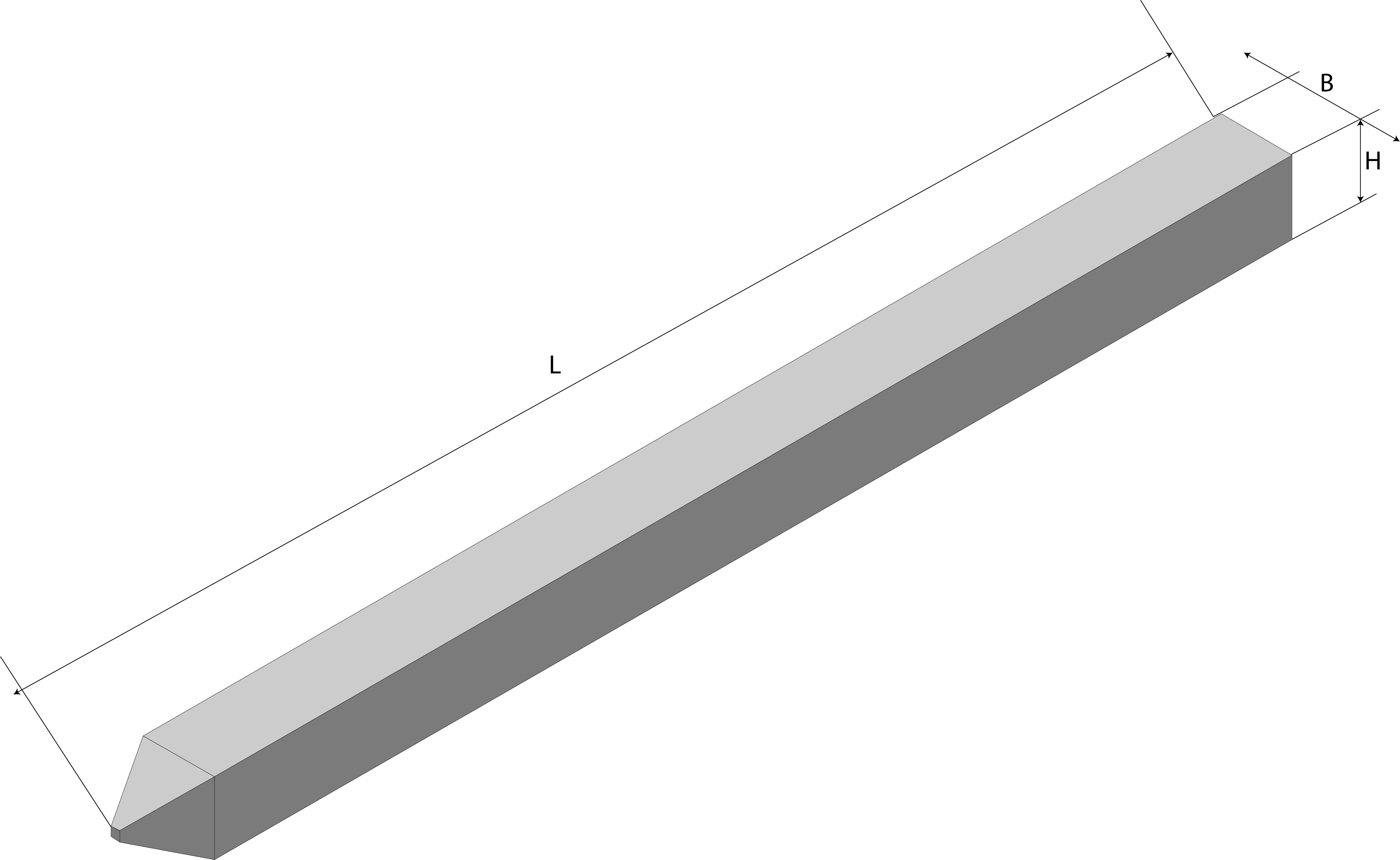

This norm applies to the design of foundations on piles, respecting the condition: the side or diameter of the current cross section of the pile, d, is: 0.3 < d: S 3.0m.

The provisions of this norm are correlated with the provisions of the system of European construction standards - EUROCODES.

This normative is in accordance with the principles set out in Section 7 of SR EN 1997-1: 2004 and SR EN 1997-1: 2004 / NB: 2007, and as the case may be, with the associated errors and amendments.

1. Input data:

Layer characteristics {{index+1}}:

2. Pile characteristics:

The length of the pile part included in the reinforced concrete screed is determined depending on the type of load and the type and diameter of the longitudinal reinforcement in the pile body (the leveling layer of concrete is not included in the screed thickness) according to specific technical regulations. In the case of foundations on piles subjected to axial stresses and horizontal forces that can be taken over by piles considered articulated in the raft, the piles must enter the raft with their heads intact on a length of 5 cm, and the longitudinal reinforcements of the piles in the screed at least 25 cm.

In the case of foundations on piles subjected to axial stresses or high horizontal forces, which require their taking over by piles considered embedded in the screed, the piles must enter the screed with intact ends at a length of at least 10 cm, and the longitudinal reinforcements of the piles must be embedded in the radier on a length determined by its constructive calculation, in compliance with the provisions of the technical norms.

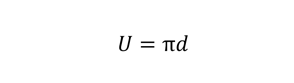

Pile diameter:

The length of the pile is established so that, through the combined effect of the friction on the side surface and the resistance in the base plane, the pile transmits to the ground the axial calculation load that belongs to him. It is recommended that the length of the large diameter drilled pile be determined according to the depth at which the practically incompressible layer meets. For piles with significant horizontal loads, the length of the pile is determined so as to ensure the necessary embedding in the field.

The depth of penetration of the pile into the load-bearing layer must be at least 2 d for piles with d <1.20 m and 1.5 d for piles with d ³ 1.20 m (d - diameter of the pile). If the load-bearing layer consists of a rock, it is allowed to embed at least 0.5 m after removing the layer of altered rock. Flaring at the base of the drilled pile is made only if the base penetrates in a layer with high cohesion, having resistance to compression with free lateral deformation (monoaxial compression) of at least 200 kPa when drilling in land and 300 kPa when drilling in water . Flaring is done in the form of a cone trunk, with a height at least equal to the diameter of the current section of the pile. It is recommended that the area of the widened base section does not exceedthree times the current section of the pile. In order to increase the load-bearing capacity of the drilled pile as well as to reduce the deformations due to the ground at the base, possibly weakened by the drilling operation, an injection can be provided at the base of the pile or along its lateral surface. For this purpose, the pipes through which the suspension is to be injected (usually cement milk) are embedded in the pile`s body, being lowered into the drilled hole together with the reinforcement housing. The recipe and injection technology are specified in the specifications.

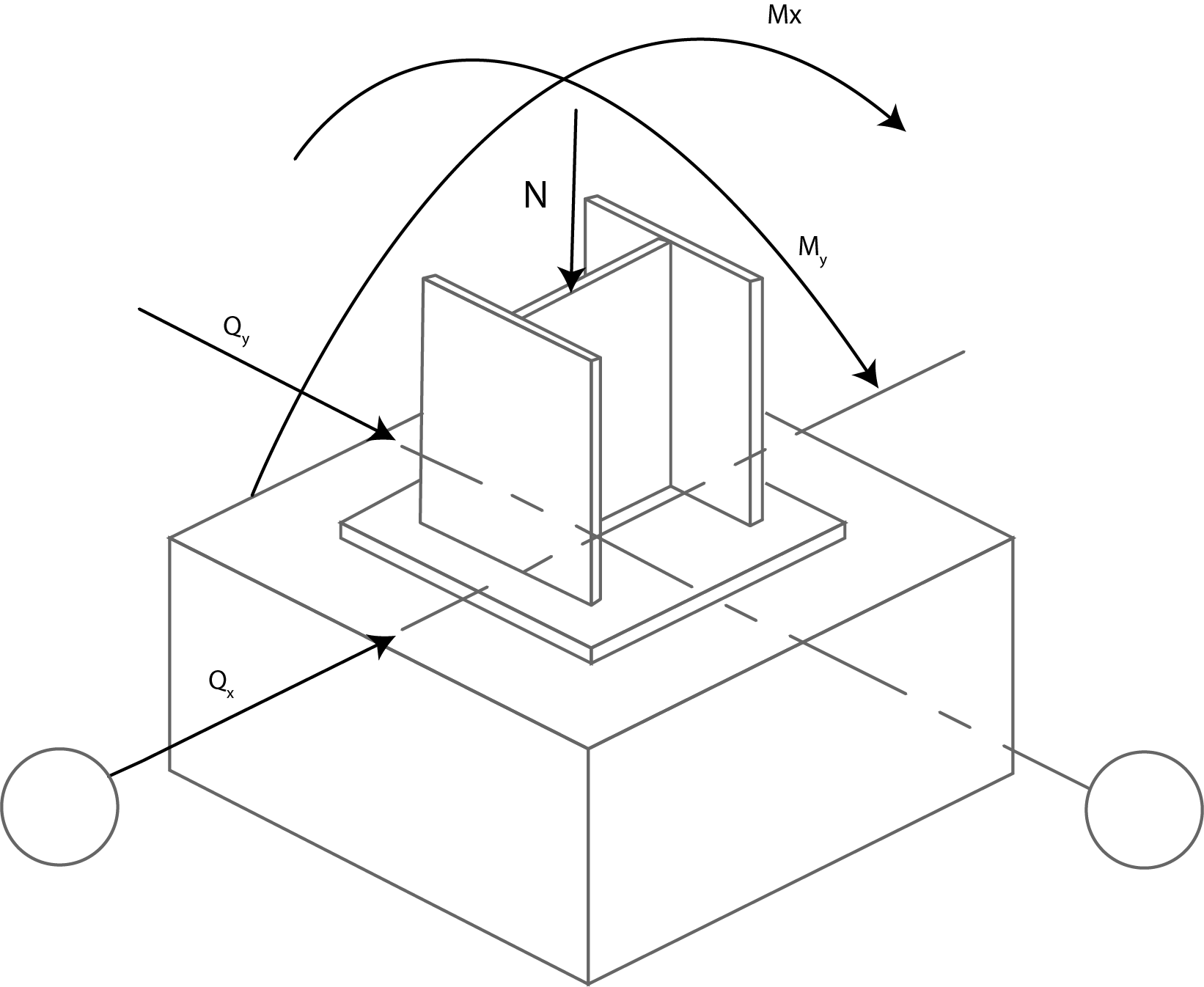

3. Loads transmitted by the superstructure:

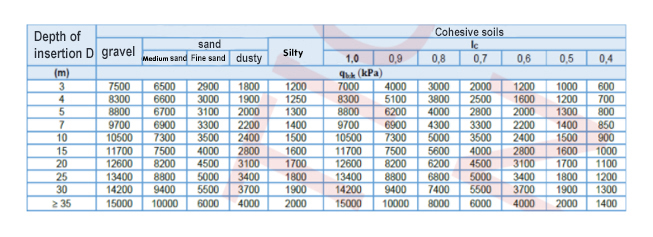

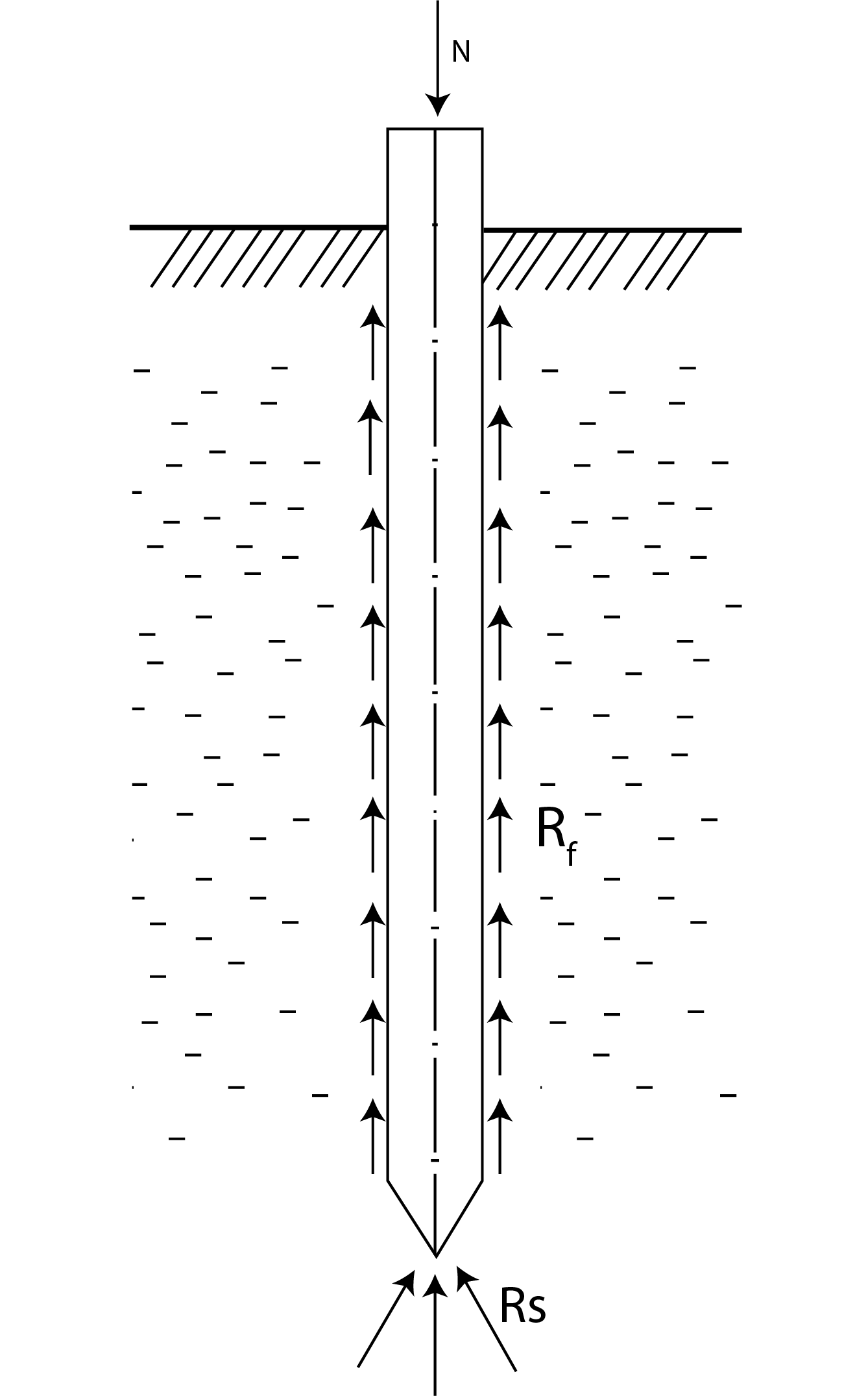

4. Pile-based resistance:

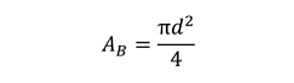

Pile base area:

For Pile with circular section

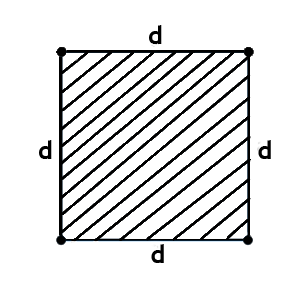

For Pile with square section

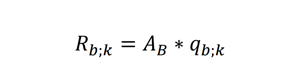

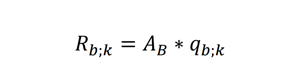

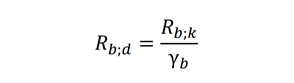

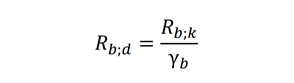

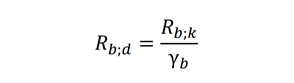

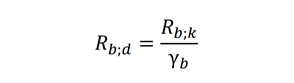

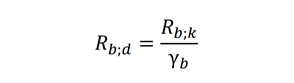

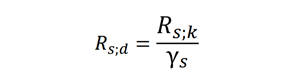

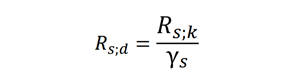

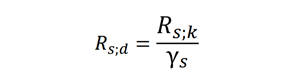

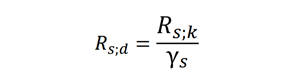

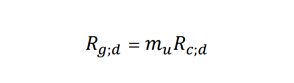

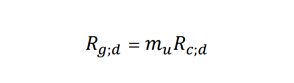

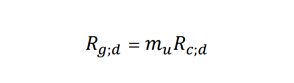

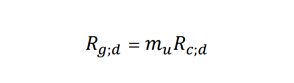

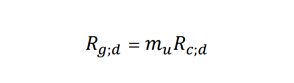

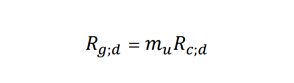

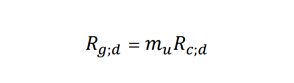

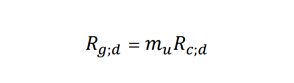

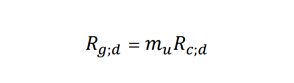

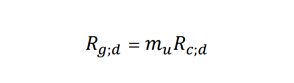

Resistance calculation value based on the pile:

The calculation value of the resistance based on the pile:

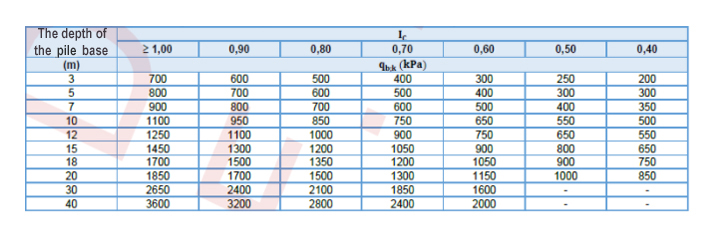

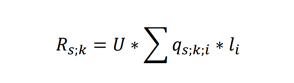

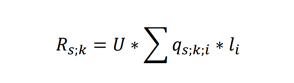

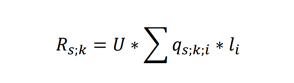

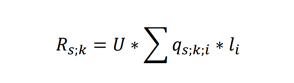

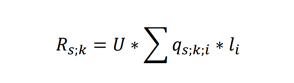

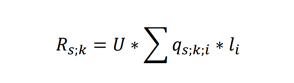

5. Frictional resistance on the side surface of the pile:

For layer {{index+1}}:

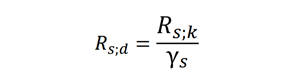

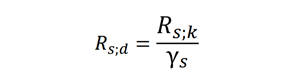

The characteristic value of the total frictional resistance on the side surface of the pile:

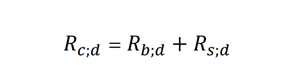

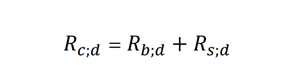

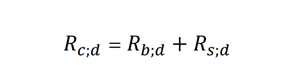

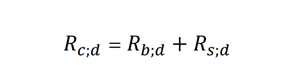

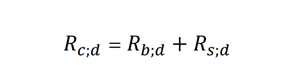

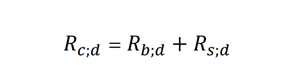

6. Compressive load-bearing capacity of the isolated pile:

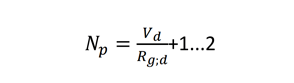

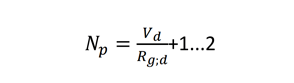

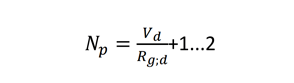

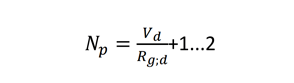

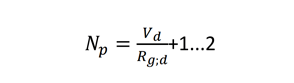

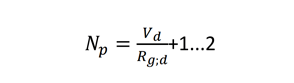

7. Determining the required number of piles

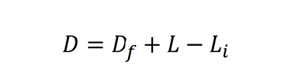

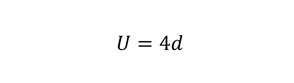

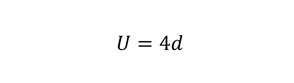

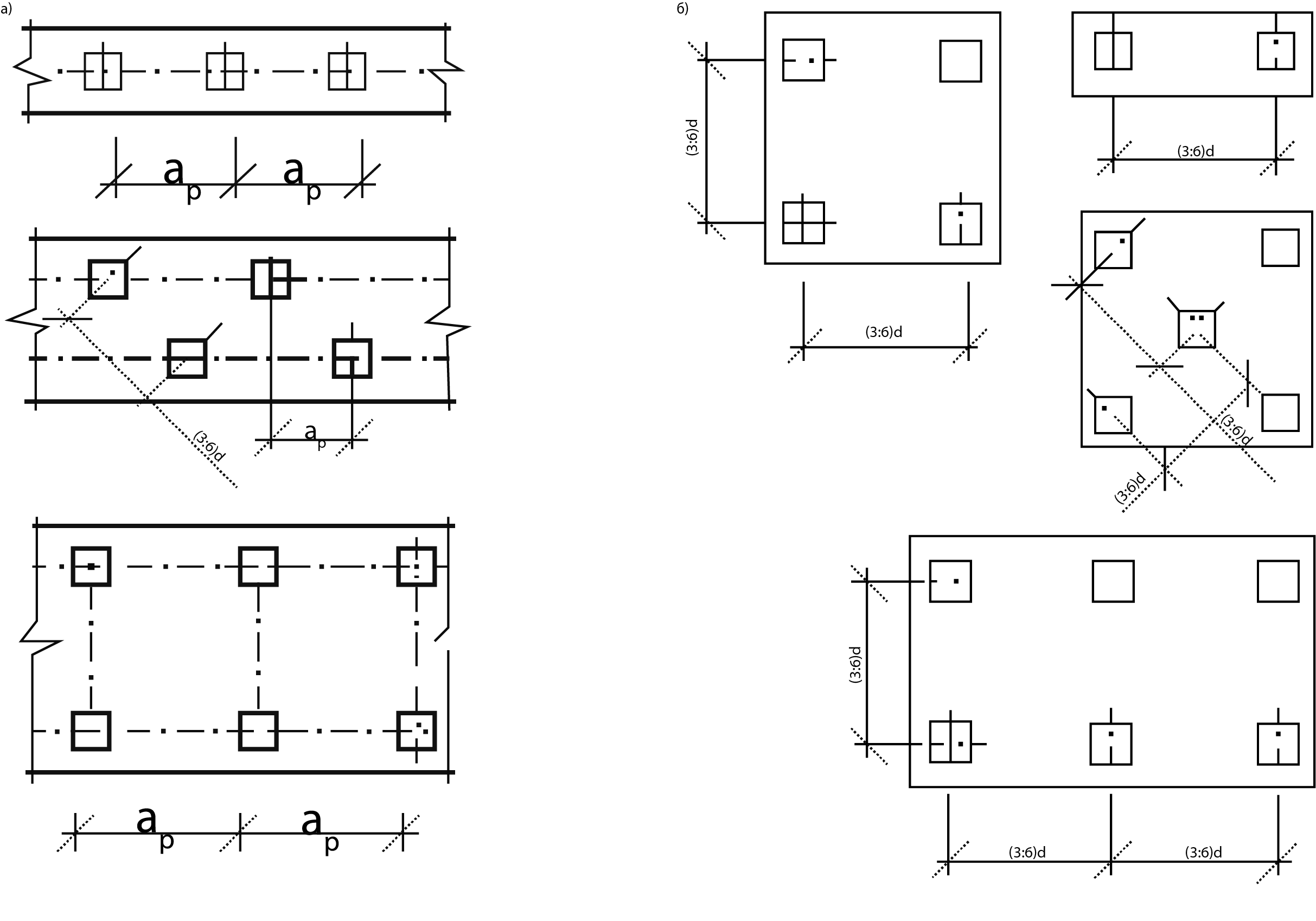

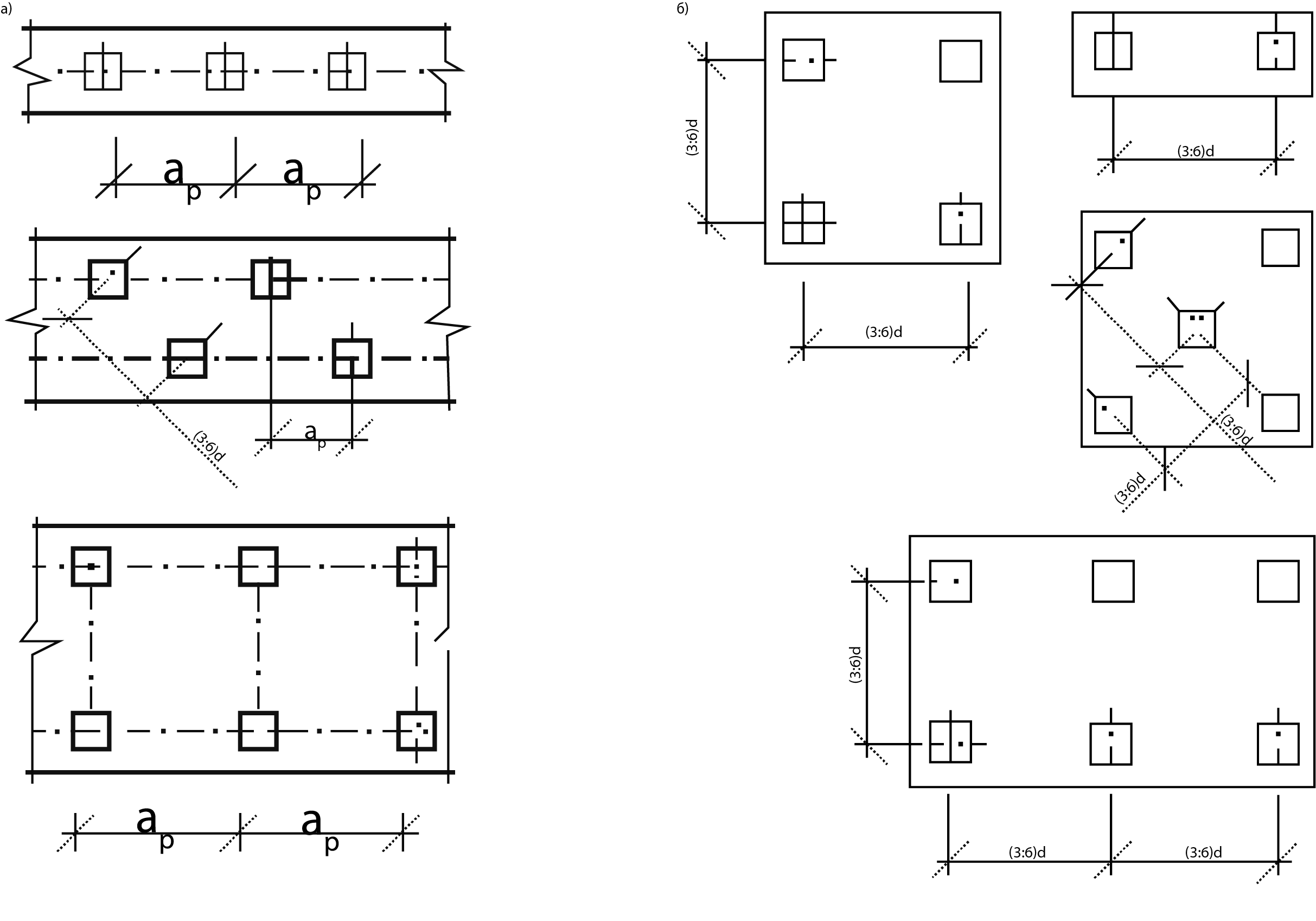

Distance between piles:

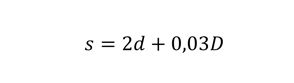

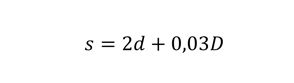

The minimum distance between the piles axes, measured in the field, is: 3d-in the case of piling or tapping piles and 2d + 0.03D-in the case of displacement piles (minimum recommended value)

Where:

d - diameter or section of the short side of the pile

D - the real file of the pile

For drilled or displacement piles:

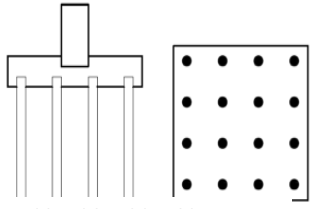

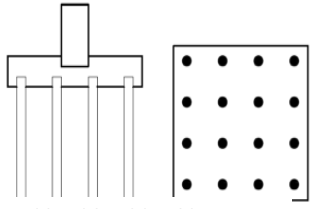

For Pile with circular section

For crowded or beaten piles:

For Pile with square section

Coefficient of efficiency:

Number of drilled or displacement piles:

For pilot with circular section

Number of piles, stuffed or beaten:

For Pile with square section

Reinforcement of piles is usually done with reinforcement housings consisting of longitudinal bars, stirrups or frets, stiffening rings and spacers. The concrete class must be at least C12 / 15 (Bc15) and will be correlated with the concrete class of the piles. The distance between the outer face of the marginal piles and the end of the screed must be at least 25 cm. The choice of concrete class, minimum cement dosage and type and size of aggregates are made in compliance with the provisions of SR EN 1536: 2004 and NE 012/1 : 2007. For piles located in lands with aggressive waters, the specific regulations must be taken into account when compiling the concreting recipe. The piles reinforcements are made, as the case may be, of steel type OB 37, PC 52 or S500.

Design of pile groups

Normally the piles are installed in the group being secured at the top with a scraper. The column is positioned on the scraper so that the load from it is evenly distributed to the individual piles in the group.

The capacity of a group is obtained using the efficiency factor.

Pile group capacity = pile group efficiency * single pile capacity * number of piles. If in a group of piles there are 16 piles and the capacity of a single pile is 30 tons and the group efficiency is 0.9 then the capacity of the group of piles is 432 tons. (0.9 * 30 * 16). Clearly high efficiency of the group of piles is desirable, it depends on the distance between the piles. , the efficiency increases, only that the size of the eraser must be larger so the cost of the eraser also increases.

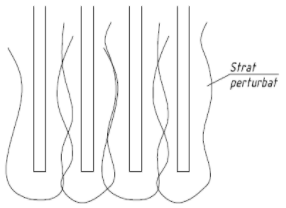

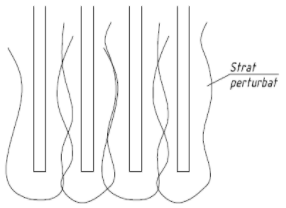

Earth disturbance during pile installation

When the piles are introduced, the ground around them is undisturbed. The disturbed ground has a lower resistance than the ground in its natural state. Some piles are introduced into the partially disturbed ground which causes a lower load-bearing capacity than in others. The disturbance of the ground caused by a pile affects the load-bearing capacity of the neighboring piles. The efficiency of the group can be improved by positioning the piles at a greater distance. In clay soils the shear strength is reduced due to the disturbance.

Earth disturbance during pile installation

When piles are introduced in a group, some piles may be bent due to the movement of the earth, this effect is more pronounced in clay soils. the introduction of the pile B can bend the pile A. Further this leads to a reduced capacity in the group.

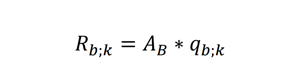

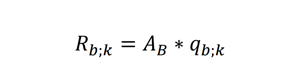

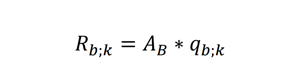

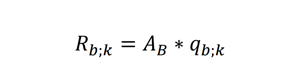

The carrying capacity on the rod of the piles:

Piles based on peak carrying capacity may not be affected by other piles in the group. Piles founded in a very resistant layer or rock, when the piles do not depend on the lateral friction, an efficiency of group work can be used = 1

The pile is piled up in sandy soils:

When piles are inserted into sandy soils, the surrounding soil will be crowded. The dense soil tends to increase the lateral friction of piles. The group of piles placed in sandy soils may have a higher capacity than the efficiency of a pile. The compaction of the soil due to the introduction of the piles will be very small in clay soils.

Total meters in the group of piles

Piles with circular section

Total meters in the group of piles with circular section

Piles with a square section

Total meters in the group of piles with a square section

To receive a copy of the calculation at your request, fill out the contact form.

Calculation form

Menu

Latest Projects

Our contacts

Adress: România, Constanța, bd. Tomis 46, cam. 3 Tel: +40736977215

E-mail: pilotipresati@gmail.com

Office Hours

Monday-Saturday: 8:00-18:00

Sunday: closed